Innovation in Polymer Coatings:

A Greener Tomorrow for Food Packaging & Energy Sectors

About us

Who We Are

At EraPolyCare, we are a passionate team of scientists, engineers, and innovators dedicated to pushing the boundaries of materials science. Our journey began with a simple yet profound question: How can we use polymer innovation to safeguard our planet for a sustainable future? With expertise spanning Food Packaging and Leak Protection, we aim to tackle industry-specific challenges while fostering environmental stewardship. By combining cutting-edge technology with a commitment to sustainability, we bridge these two diverse sectors to deliver solutions that are both innovative and impactful

Why Choose EraPolyCare?

Materials Expertise: Two decades of experience in solving complex challenges with advanced polymer and composite solutions.

Tailored Solutions: Customizable products and services to meet the unique needs of every client and application.

Cross-Industry Knowledge: Bridging the gap between diverse industries with a shared focus on safety, performance, and efficiency.

Sustainability Commitment: Dedicated to reducing waste and environmental impact through cutting-edge material innovation.

Our Mission

At EraPolyCare, we specialize in polymer coating technologies, from design and manufacturing to contractor services. We deliver high-performance, sustainable solutions that protect food, pharmaceuticals, and energy sectors, ensuring enhanced product integrity and environmental stewardship.

Our Vision

We aim to lead the polymer coating industry by driving sustainable innovation, improving product performance, and minimizing environmental impact. Our focus is on providing cutting-edge solutions that support a circular economy and contribute to a safer, more sustainable future.

OUR SERVICES:

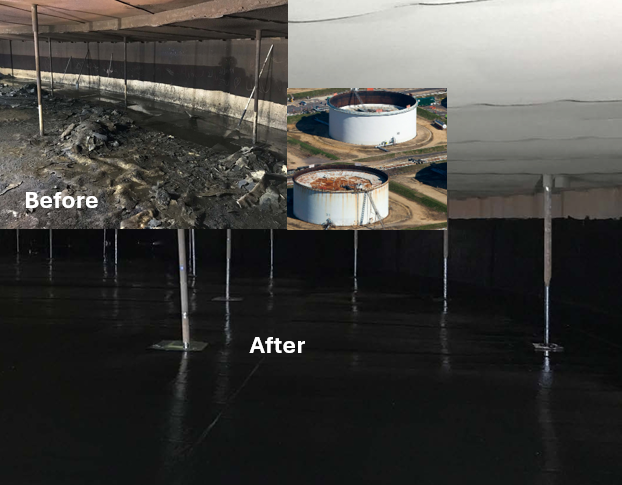

CorroGuard Structure for Steel /Concert Structure Rehabilitation

Era PolyCare Structural Rehabilitation team provides advanced solutions for repairing and restoring corroded structures across various industries. Whether it’s concrete, steel pipes, tanks, or other critical infrastructure, our cutting-edge repair techniques use high-performance materials to improve durability and prevent future corrosion. Offering a cost-effective alternative to full replacement, Era PolyCare extends the lifespan of your assets while minimizing downtime and environmental impact. Count on Era PolyCare to restore the strength and integrity of your infrastructure, ensuring safety and long-term reliability.

OUR PRODUCTS

At Era PolyCare, we innovate to deliver advanced solutions that enhance performance, sustainability, and reliability across diverse industries. Explore our range of cutting-edge products tailored for the challenges of today and tomorrow:

PolyCare Guard: A High Barrier Coating for Food and Pharmaceutical Packaging

Engineered for excellence, PolyCare Guard offers unparalleled oxygen and moisture barrier properties, ensuring optimal freshness and quality for packaged goods.

Key Features:

Mono Layer Biodegradable Polymers: Environmentally friendly materials for reduced ecological impact.

Superior OTR (Oxygen Transmission Rate): Exceptional barrier performance to preserve food and pharmaceutical integrity.

High WVTR (Water Vapor Transmission Rate): Protects against moisture and spoilage.

Applications:

Flexible packaging, thermoforming, film blowing and extrusion process.

Work well with both polymer film and paper applications.

Benefits:

Food Packaging: Keeps dry food fresh and extends shelf life.

Pharmaceutical Packaging: Maintains product efficacy and safety.

Composite Patch for Marine and Offshore

For marine and offshore applications, our diver-applied composite patches offer a revolutionary and durable solution for repairing both metal and composite structures.

Key Features:

Cures at 5°C within 6 hours, inimizing downtime.

Underwater Application: Diver-applied, eliminating the need for dry-docking or costly repairs.

Crack Arresting Technology: Prevents crack propagation, ensuring long-term durability.

ISO21809-1:2011(E) Compliant: Meets international standards for corrosion protection and composite repair.

Applications:

Ship Hulls & Decks: Suitable for steel and aluminum surfaces.

Offshore Pipelines & Structures: Reliable for underwater rehabilitation.

Benefits:

Crack arresting capabilities for enhanced durability.

Options for long-term or temporary emergent repairs.

Exceptional resilience under extreme conditions.